Extraction System

SKE offers high-grade extraction technology and plants for making extracts for cosmetic, food, beverage and pharmaceutical industries. We specializes in project planning and manufacturing of extraction plants and will support you to achieve your production targets.

Advanced Solutions for Efficient and High-Quality Extraction

Extraction Plant from SKE Equipment is designed to deliver high-performance extraction processes across a wide range of industries, including pharmaceuticals, food and beverages, and chemicals. Our state-of-the-art extraction systems are engineered for precision, efficiency, and scalability, ensuring that you achieve the highest quality extracts while maintaining cost-effectiveness and sustainability. Whether you’re extracting natural ingredients, active pharmaceutical ingredients (APIs), or chemical compounds, our extraction plant solutions meet the most demanding requirements of your operations.

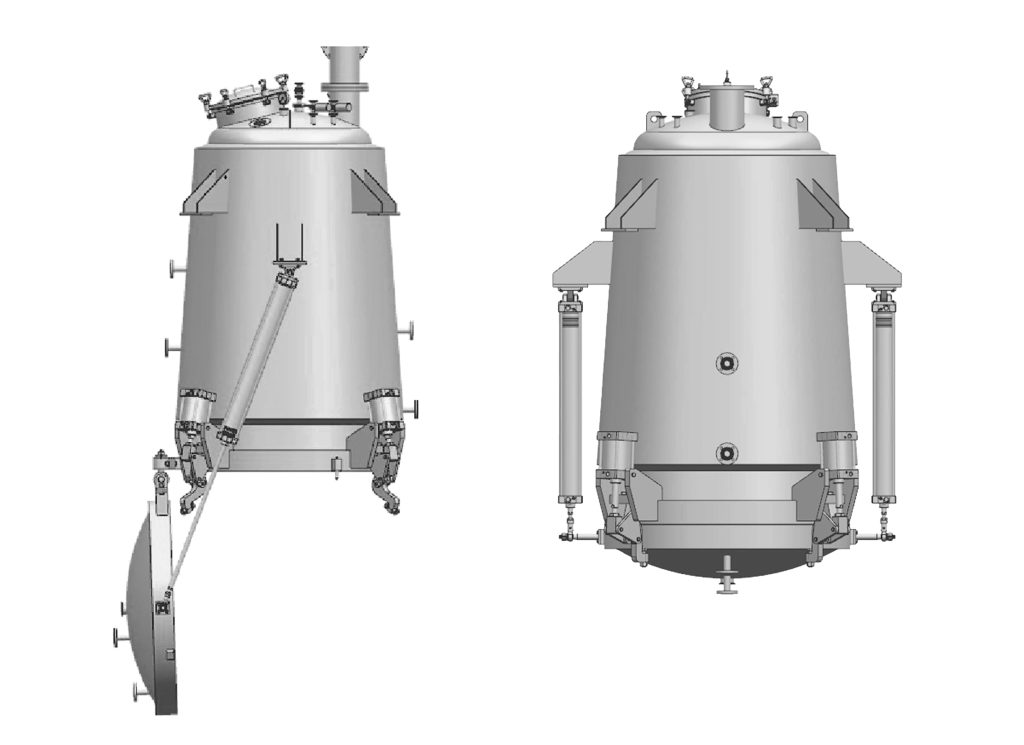

SKE multi-function Extractor/ Extraction tank

- Using inverted -cone design, first is conducive to the residue discharge, and will not appear bridging phenomenon, without any auxiliary personnel; another advantage is herbal extraction process in favor of tumbling, making extraction more uniform.

- Bottom area increased, increasing the filtration area and reduce the liquid circulation and the chance of clogging of the process.

- Segmented controlled heating, can effectively prevent bumps; and increase the flexibility of feeding amount to prevent sticking to the wall of the upper Griddle.

- Bottom with a heating device, just open the bottom heating during boiling process, effectively prevent explosive boiling and save energy.

Starting with the base data such as pressure, temperature, solvents, dwell times and other details to make full use of the raw material, SKE team will design, manufacture and install the functional plant for your facility.

- Fully automatic control system with recipe storage, remote control.

- Optional with vacuum system for better extract flow and solvent recovery.

- Optional with mixer system

- Multi effect extractor group

- Multi heating jacket design for different boiling level to save energy

- High extraction rate

- Easy discharge and easy CIP

Have Questions? Request a Quote, Demo, or More Information

Once we receive your inquiry we’ll get in touch asap.